Advantages and disadvantages of titanium alloy!

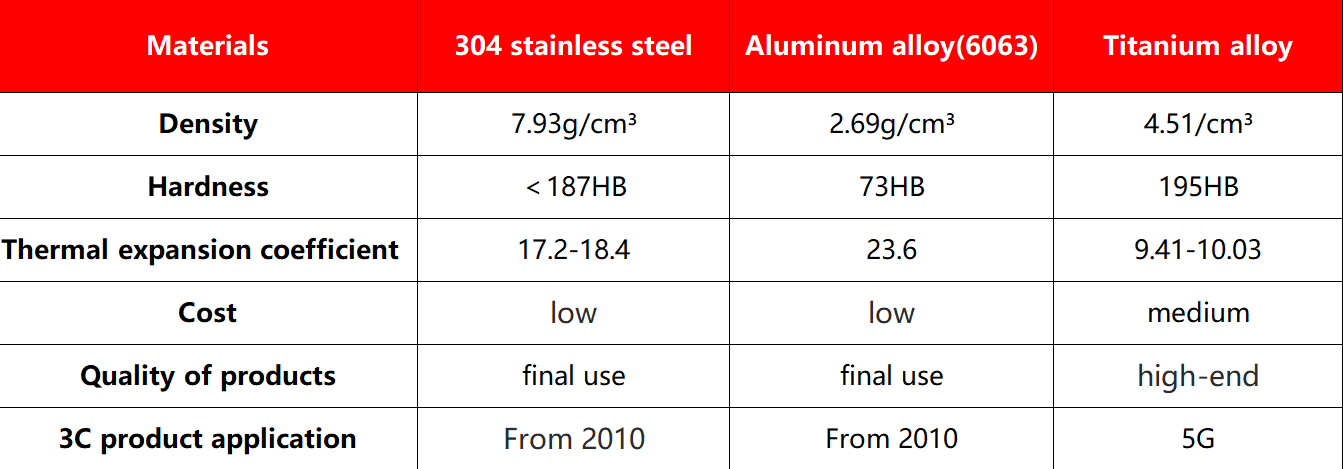

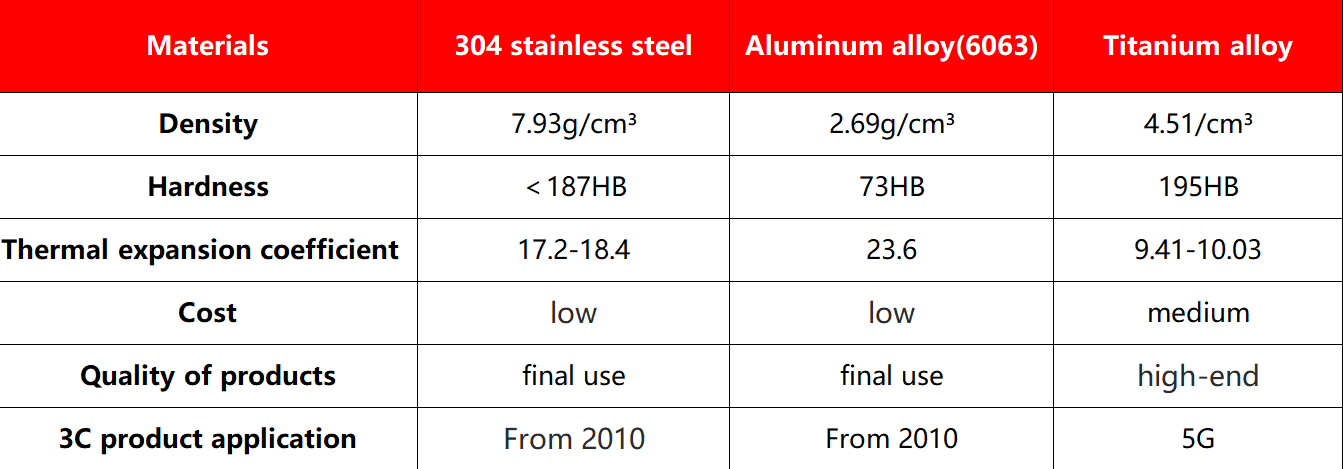

1. High strength and low density. The density of titanium alloy is generally about 4.51g/ cubic centimeter, only 60% of steel, some high strength titanium alloy exceeds the strength of many alloy structural steel.Therefore, the specific strength (strength/density) of titanium alloy is much higher than that of other metal structural materials, which can produce parts with high unit strength, good rigidity and light weight.

2. high thermal strength. It can still maintain the required strength at a moderate temperature, and can work for a long time at a temperature of 450 ~ 500℃. These two types of titanium alloy still have a high specific strength in the range of 150 ~ 500℃. The working temperature of titanium alloy can reach 500℃, and aluminum alloy is below 200℃.

3. low temperature performance is good. Titanium alloy can still maintain its mechanical properties at low and ultra-low temperatures. Titanium alloys with good low temperature performance and very low gap elements, such as TA7, can still maintain a certain plasticity at -253℃. Therefore, titanium alloy is also an important structural material at low temperature.

4. Low thermal conductivity and elasticity. Titanium thermal conductivity λ=15.24W/ (m.K) about 1/4 nickel, iron 1/5, aluminum 1/14, and the thermal conductivity of various titanium alloy than the thermal conductivity of titanium decreased by about 50%.The elastic modulus of titanium alloy is about 1/2 of steel, so its poor rigidity, easy deformation, not suitable for the production of slender rod and thin-walled parts, cutting processing surface of a large amount of springback, about 2 ~ 3 times of stainless steel, resulting in intense friction, adhesion, bonding wear after the tool surface.

5. the chemical activity is large. The chemical activity of titanium is large, and the atmosphere O, N, H, CO, CO2, water vapor, ammonia and other strong chemical reaction titanium chemical affinity is large, easy to produce adhesion phenomenon with the friction surface.

What can we offer for knife design?

What can we offer for knife design?

Why do you need a knife outdoors?

Why do you need a knife outdoors?

Is titanium magnetic?

Is titanium magnetic?

what is the titanium Apple phone15 Pro case that everyone is using like?

what is the titanium Apple phone15 Pro case that everyone is using like?